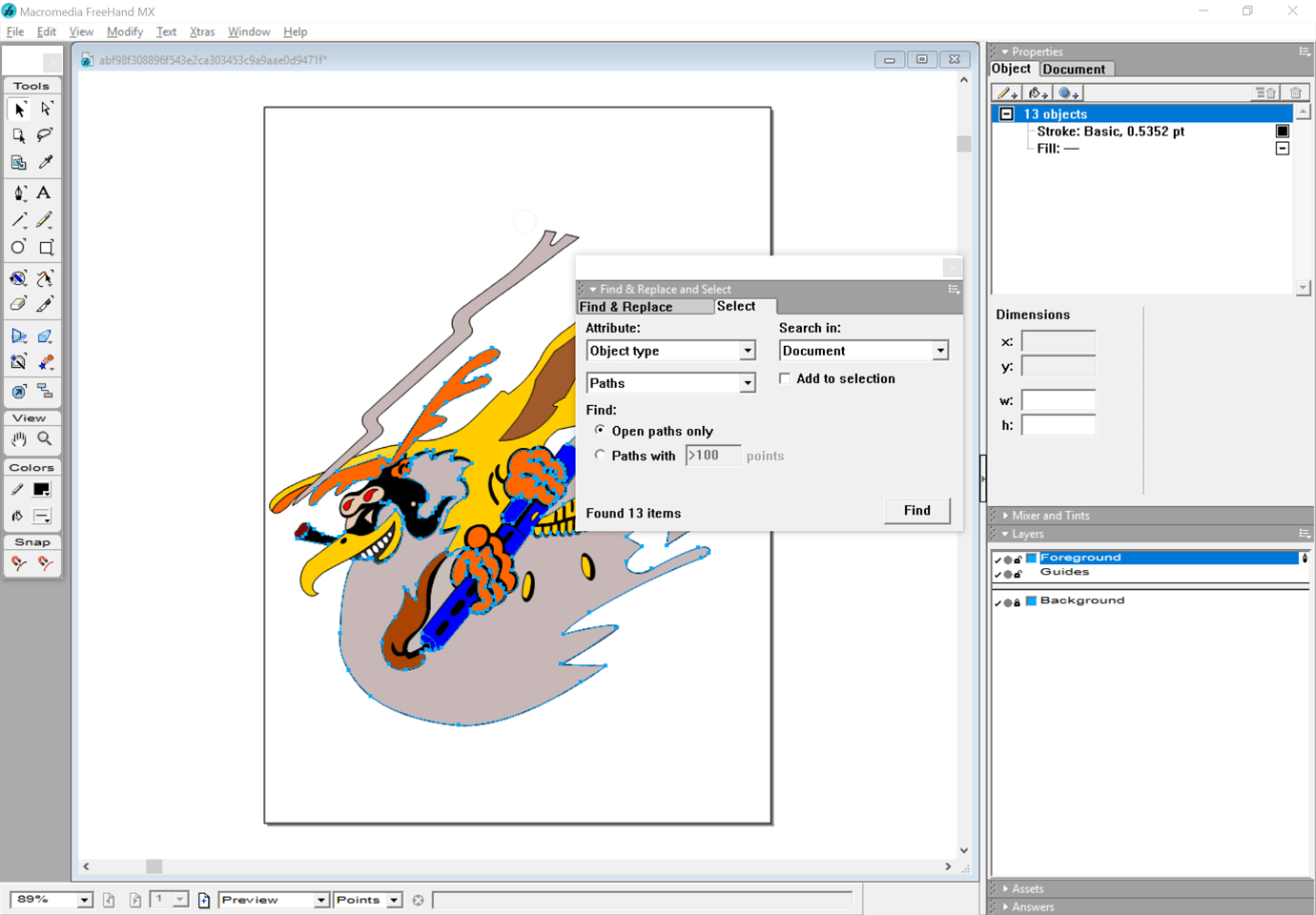

In the Post Process dialog change the source to “My Cloud Posts” and select the ShapeOKO.cps as the post processor.ĭrop the ShapeOKO.cps into the CAMPosts directory on the cloud drive Drop the ShapeOKO.cps in there and it will now show up with the cloud enabled settings. Go to you A360 Drive and off the “Top” you’ll see a directory named “CAMPosts”. With the recent version of Fusion 360 the parameters can be saved in the cloud drive and accessed on all platforms. Even better the settings can be toggled at runtime, on windows at least, by changing the parameters.

This makes the first move with the tool not drag the bit close to the top of the work. This sets it to 15mm (assuming the machine is in mm mode) above the work. The startup Gcode comes out looking like this: % The next time I ran my cam job and called the post-processor I selected my ShapeOKO.cps. I added a couple customizations to toggle wether G28 or a “safe” Z height should be used and saved the file. The post processors appear to be coded in some type of Javascript and are fairly easy to understand. These were stored in “/Users//Library/Application Support/Autodesk/webdeploy/production//Libraries/Applications/CAM360/Data/Posts” I copied the grbl.cps to ShapeOKO.cps and started hacking away. I dug around to find the post-processors (conveniently matching their name) for grbl using Finder on my mac. Ideally the first move would occur at the safe height then plunge down into the work from that height. Instead of the G28 G91 Z0 we want to move the tool to a safe Z-height before it turns on the tool and moves it for the first cut. The G28 would normally take care of this if you have limit switches and it is enabled in grbl. This in itself is fine but the first thing that happens is the tool is started right at the surface of the work instead of moving it up a safe distance. The default startup G-Code using the grbl post processor looks like this: % Limit switches would need to be installed for this to work and for it to be turned on in grbl. However when exporting the G-Code through the grbl post-processor I discovered the G-code was using G28 (return to home) which isn’t supported in a stock ShapeOKO 2. Designing the part was quick and so was setting up the CAM operation. I managed to fumble my way through making some quick designs and setting up a simple cam job to make a tool holder.

I recently started playing around with Autodesk’s Fusion 360 3D modeling and CAM software.

0 kommentar(er)

0 kommentar(er)